Choosing the Right Diecast Model Car Paint

The journey of transforming a diecast model car from its factory finish to a custom masterpiece begins with the right paint. Selecting the appropriate paint is crucial, as it directly impacts the final look, durability, and overall satisfaction of your project. Several factors come into play when choosing paint, including the type of paint, the desired finish, and the level of experience you have. Understanding these aspects ensures you’re equipped to make an informed decision, setting the stage for a successful and enjoyable painting experience. Remember that the best paint for your model car is the one that meets your specific needs and preferences, leading to a stunning and long-lasting finish. Before you even pick up a brush or a spray can, take the time to research and understand your options.

Types of Paint for Diecast Models

The world of diecast model car painting offers a diverse array of paint types, each with its unique characteristics and benefits. The most common types include acrylics, enamels, and lacquers. Each paint type boasts distinct properties regarding application, drying time, durability, and the overall finish they provide. The selection of paint will greatly influence your painting process and the final appearance of your model car. It is essential to understand the differences between each type of paint to make the right choice for your project. This will ensure not only a stunning look but also the longevity of your painted model.

Acrylic Paints

Acrylic paints have become a popular choice for diecast model car enthusiasts due to their ease of use, low odor, and quick drying times. Acrylics are water-based, making them simple to clean up with water and reducing the need for harsh solvents. They are available in a vast range of colors and finishes, allowing for extensive customization. Acrylic paints are also known for their flexibility, which helps prevent cracking and chipping over time, particularly on plastic or resin models. While acrylics offer excellent versatility, it’s essential to note that they may require more coats to achieve a smooth and even finish compared to other types. Acrylics are a great option, especially for beginners, providing a user-friendly and versatile experience. They are ideal for airbrushing and brush application, making them adaptable to various painting techniques.

Enamel Paints

Enamel paints are known for their durable, glossy finishes, making them a favorite for many model car enthusiasts. Enamels typically have a longer drying time than acrylics, allowing for more time to work and correct any mistakes. Enamel paints are oil-based and often require the use of solvents for thinning and cleanup. While they provide excellent coverage and a smooth finish, they can be more challenging to work with than acrylics due to their longer drying times and the need for proper ventilation. However, the results are often worth the effort, as enamel paints offer a resilient finish that can withstand handling and exposure to the elements. Many modelers prefer enamel for its classic look and robust protection. Be sure to use the appropriate thinner and follow safety guidelines when working with enamel paints.

Lacquer Paints

Lacquer paints are renowned for their rapid drying times and incredibly smooth finishes, perfect for achieving a professional look. Lacquers contain solvents that evaporate quickly, leading to a hard and durable surface in a short amount of time. These paints are popular among experienced modelers due to their fast application and ability to create a stunning gloss. However, working with lacquers requires caution, as they release strong fumes and need proper ventilation. They also demand precision during application, as the quick drying time leaves little room for error. Lacquer paints are best suited for experienced modelers seeking high-quality finishes and are often used for achieving a realistic, showroom-worthy look. Safety equipment, including a respirator, is highly recommended when using lacquers.

Preparing Your Diecast Model Car for Paint

Preparation is the cornerstone of a successful diecast model car paint job. Proper preparation ensures that the paint adheres correctly, resulting in a smooth, professional finish. This phase includes cleaning, sanding, and priming the model’s surface. It is the most crucial step, as any imperfections or contaminants on the surface will show through the paint, ruining the final result. The time and effort invested in preparation are directly proportional to the quality of the final paint job. Do not rush this process; it is the key to a flawless finish. Taking the time to prepare your model carefully will give you a beautiful, long-lasting finish. The following steps are essential for optimal paint adhesion and appearance.

Cleaning the Model Surface

Before you even consider applying paint, it’s essential to clean the diecast model thoroughly. Diecast models often have a layer of mold release agent, dirt, or oils that can interfere with paint adhesion. Using warm, soapy water, gently wash the entire model, paying close attention to crevices and hard-to-reach areas. A soft brush or toothbrush can help remove stubborn grime. After washing, rinse the model thoroughly with clean water to remove all soap residue. Allow the model to air dry completely before proceeding to the next step. Properly cleaning the surface ensures that your paint will adhere well, giving you a smooth and even finish. Do not skip this step, as it’s critical for a professional-looking result.

Sanding and Priming

Sanding and priming are vital steps to prepare your diecast model for paint. Sanding helps to smooth out any imperfections, such as scratches or casting marks, and provides a surface that the primer can grip. Start with a medium-grit sandpaper (around 400-grit) to remove any blemishes and then gradually move to finer grits (600-1000 grit) for a smoother surface. After sanding, thoroughly clean the model to remove any sanding dust. Priming creates a base for your paint, promotes adhesion, and helps the color of the topcoat appear more vibrant. Apply a thin, even coat of primer, allowing it to dry completely before sanding lightly with a fine-grit sandpaper (1000-1200 grit). This process creates an ideal surface for your topcoat, making the painting process much more successful and ensuring a professional finish. Use a primer that is compatible with your chosen paint type.

Masking and Detailing

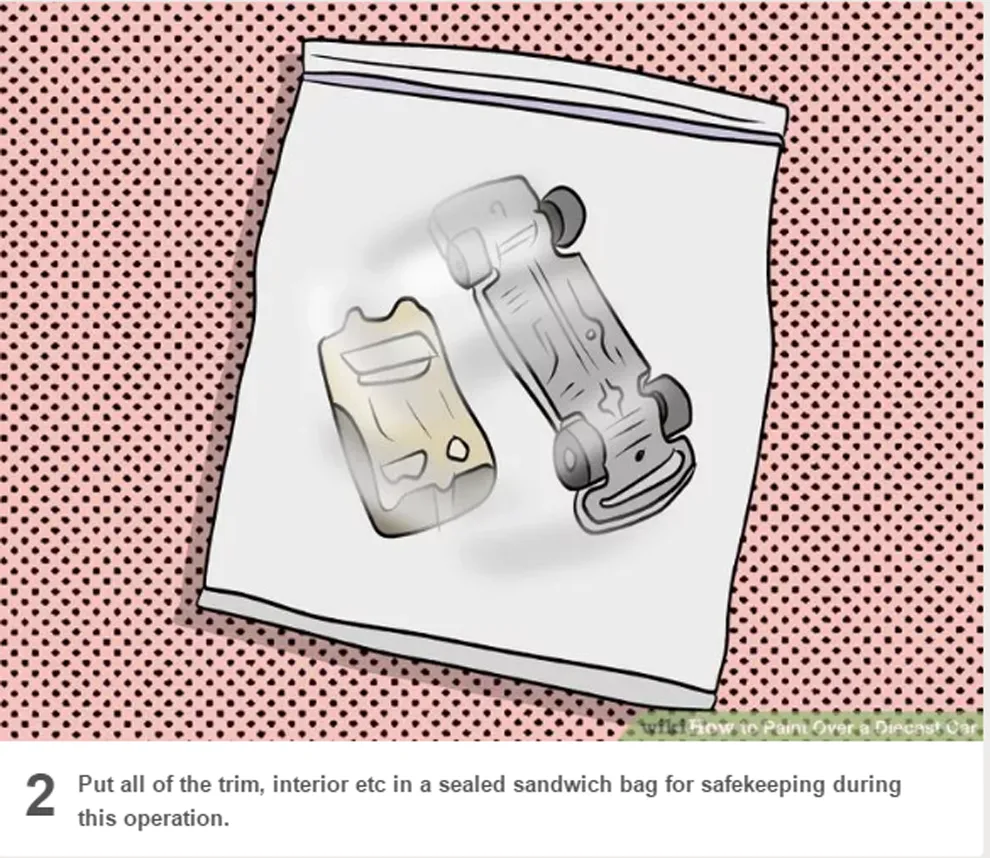

Masking and detailing are critical for achieving crisp lines and adding intricate details to your diecast model. Masking involves using tape to protect areas you don’t want to paint, such as windows, chrome trim, or other details. Use high-quality masking tape designed for model painting to avoid paint bleed. Carefully press the tape edges to create a tight seal. For complex curves, consider using masking fluid. Detailing involves painting small parts like lights, emblems, or interior components. Use fine-tipped brushes and steady hands for this task. Take your time and work methodically to achieve the desired level of detail. Precise masking and detailing can significantly enhance the realism and overall appearance of your model. It’s this attention to detail that separates a good paint job from a great one.

Applying the Paint [Step-by-Step]

The application of paint is where your vision for the diecast model car comes to life. It’s a process that requires patience, precision, and an understanding of your chosen paint type. Whether you’re using an airbrush or spray cans, the goal is to apply thin, even coats, building up the color gradually. Avoid applying thick coats, as this can lead to runs, sags, and a textured finish. The number of coats needed will vary depending on the paint type and desired finish. Allowing each coat to dry completely before applying the next is crucial. With careful application, you can achieve a smooth and stunning paint job that enhances the model’s overall appearance and realism. Always follow the manufacturer’s instructions for your specific paint.

Thinning and Airbrushing Techniques

Airbrushing is a popular method for applying paint to diecast models because it offers excellent control and the ability to achieve smooth, even finishes. Proper thinning of your paint is crucial for airbrushing. Use a thinner recommended by the paint manufacturer and mix it with the paint in the appropriate ratio. This ensures that the paint flows smoothly through the airbrush and adheres correctly to the model’s surface. When airbrushing, maintain a consistent distance from the model and move the airbrush in a steady, even motion. Apply thin coats, building up the color gradually. Avoid over-spraying, which can lead to runs or a textured finish. Practice on a test surface before painting your model to refine your technique. Airbrushing is a skill that improves with practice, so don’t be discouraged if your first attempt isn’t perfect.

Using Spray Cans

Spray cans provide a convenient and accessible way to paint diecast models, offering a quick and easy way to achieve a professional-looking finish. To use spray cans effectively, start by preparing the model as described previously, ensuring it is clean, sanded, and primed. When spraying, hold the can approximately 8-10 inches from the model, and apply thin, even coats. Avoid spraying too much paint in one area, as this can lead to runs or drips. Use a sweeping motion, overlapping each pass slightly to ensure even coverage. Allow each coat to dry completely before applying the next one. For best results, apply multiple thin coats rather than one thick coat. Spray cans are a great option for beginners and experienced modelers. A steady hand and a bit of practice will result in a beautiful finish.

Avoiding Common Painting Mistakes

Even experienced modelers can encounter mistakes when painting. Understanding and avoiding common pitfalls will significantly improve your results. Addressing these issues promptly can save you time, frustration, and the need to start over. By being aware of these potential problems, you can ensure a higher quality paint job.

Runs and Sags

Runs and sags are among the most frustrating painting issues, resulting from applying too much paint in a single coat. These occur when the paint pools and gravity causes it to drip or sag. The best way to avoid runs and sags is to apply thin, even coats, allowing each layer to dry before applying the next. If you notice a run or sag, let the paint dry completely, then carefully sand the affected area smooth. You can then repaint the spot, taking care to apply thinner coats. Careful application and patience are key to preventing runs and sags. Always build up the color gradually to avoid this issue.

Dust and Contamination

Dust and other airborne particles can ruin an otherwise perfect paint job. These particles settle on the wet paint, creating a rough, uneven surface. To minimize dust contamination, paint in a clean, well-ventilated area. Ensure the work area is free of dust and debris. If you find dust particles on your model after the paint has dried, you can try to remove them by lightly sanding the surface with very fine-grit sandpaper and then polishing it. However, it’s better to prevent dust contamination in the first place. Regularly clean your work area and consider using an air filter or dust-proof enclosure.

Finishing Touches for Your Painted Model

Once the paint has dried completely and any imperfections have been corrected, it’s time for the finishing touches. These steps add depth, shine, and protection to your painted model, bringing the whole project together. The finishing touches provide the final touches that will make your model stand out. This is the moment where you’ll see all your hard work come together. The final steps provide a stunning finish that protects your work and makes it truly shine.

Clear Coating and Polishing

Applying a clear coat provides protection and enhances the finish of your model. The clear coat adds a layer of durability, protecting the paint from scratches, UV damage, and other environmental factors. Clear coats are available in various finishes, from matte to glossy. Choose the one that best suits your desired look. After the clear coat has dried, you can polish the model to further enhance the shine. Polishing removes any imperfections and creates a smooth, glossy finish. Use a polishing compound and a soft cloth to gently polish the surface. Proper clear coating and polishing are critical for a professional-looking finish and will make your model car truly stand out. Taking the extra time to do this right is worth the effort.