What are Diecast Decals

Diecast decals are essentially miniature stickers or transfers specifically designed for application on diecast model vehicles. These decals allow modelers to add intricate details, markings, logos, and liveries to their models, transforming a basic diecast car into a highly realistic replica. They’re an essential component of the diecast detailing process, enabling enthusiasts to replicate real-world vehicles with remarkable accuracy. From subtle racing stripes to complex sponsor logos, diecast decals open up a world of customization options, allowing for the creation of unique and personalized models that stand out.

Understanding Diecast Decals

Diecast decals are typically printed on thin, flexible carrier sheets that are designed to adhere to the contours of a diecast model. The adhesive is activated by water, allowing the decal to be easily positioned and applied. Once in place and dry, the decal bonds with the surface of the model. The quality of a diecast decal is determined by the printing technology used, the quality of the inks, and the durability of the adhesive. High-quality decals are thin, flexible, and resistant to fading or damage, ensuring a long-lasting and visually appealing finish. Understanding this structure is key to successful application.

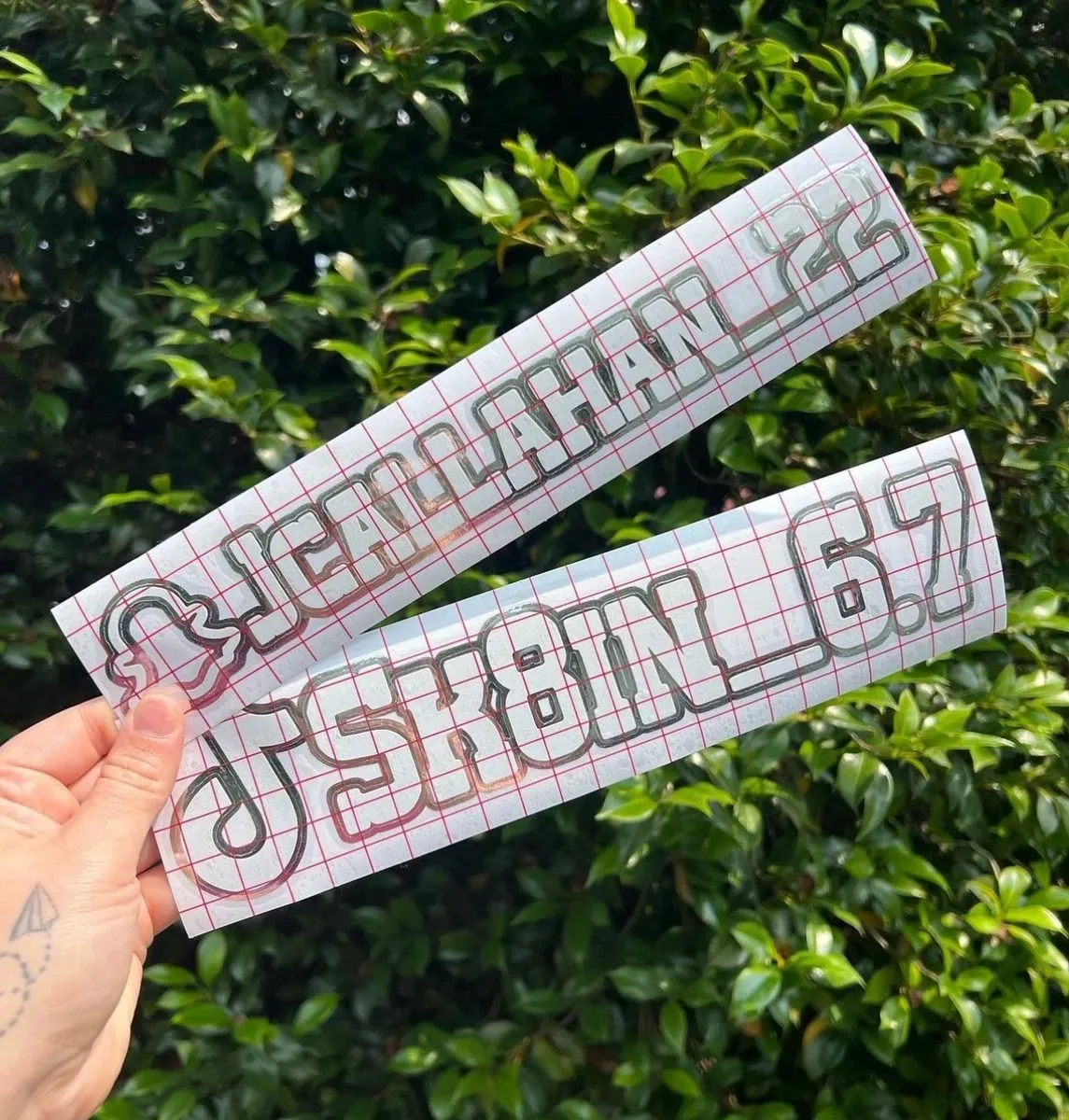

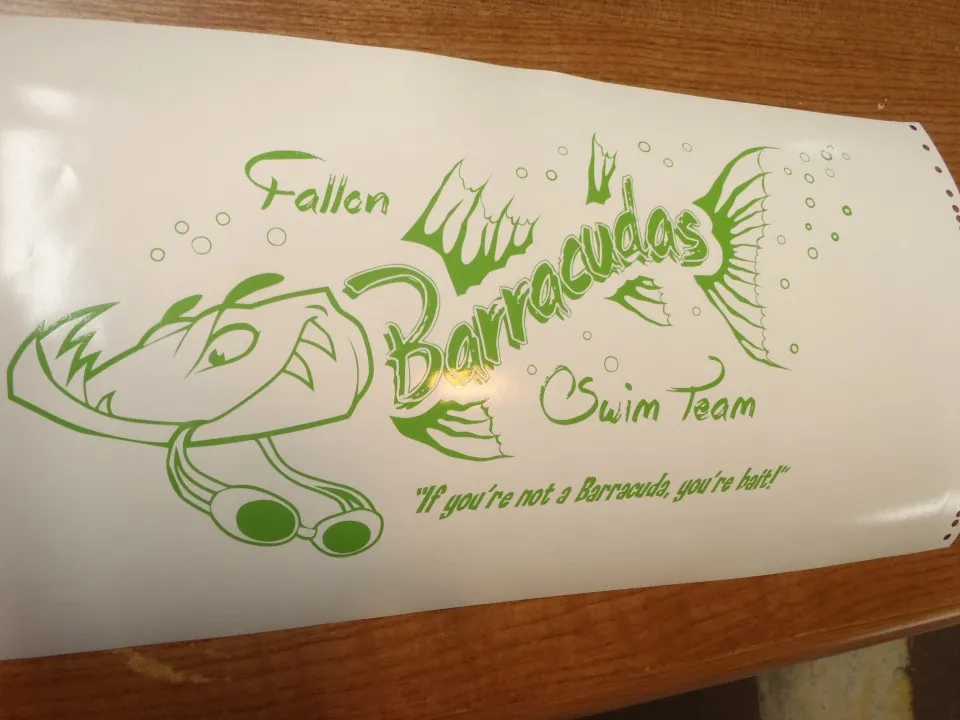

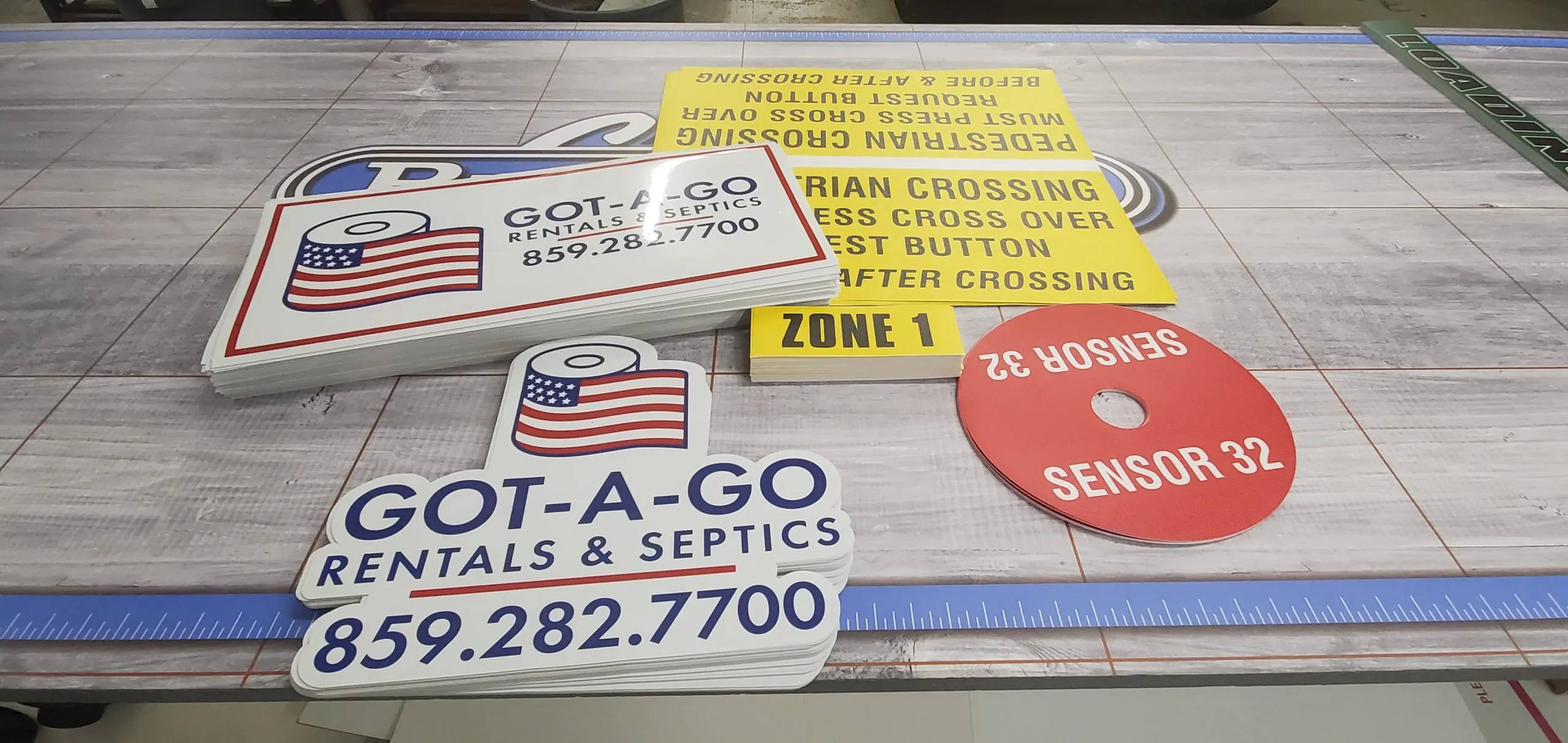

Types of Diecast Decals

There are a few main types of diecast decals. Waterslide decals are the most common type, and they are activated by soaking them in water. Dry transfers are another option; these use a burnishing tool to transfer the ink directly onto the model’s surface. Finally, vinyl decals are sometimes used, especially for larger markings, and these are usually applied using their own adhesive backing. The choice of decal type often depends on the specific project, the level of detail required, and the modeler’s preference. Each type has its own advantages and disadvantages in terms of ease of application, durability, and the level of detail that can be achieved. Consider which one suits your needs.

Choosing the Right Decals for Your Model

Selecting the right decals is critical for achieving the desired look. Consider the scale of your model, as decals are usually designed to fit specific scales (1:18, 1:24, 1:43, etc.). Ensure that the decals are of high quality, with crisp printing and accurate colors. Research the specific markings you need, whether it’s a particular racing livery, a military vehicle’s insignia, or a classic car’s emblems. Measure the areas where the decals will be applied to ensure a proper fit, and consider any curves or contours on the model’s surface. Look for decals made from durable materials that can withstand handling and exposure to the elements. Choosing wisely guarantees that the final result is accurate and visually appealing.

Preparing Your Diecast Model for Decals

Proper preparation is essential for successful decal application. Before applying any decals, clean the model thoroughly. This involves removing any dust, dirt, grease, or fingerprints that could interfere with the decal’s adhesion. Use a mild soap solution or a specialized model cleaner to clean the surface. Ensure the model is completely dry before proceeding. Examine the model’s surface for any imperfections, such as scratches or uneven areas. Addressing these imperfections beforehand will ensure the decals lay flat and look their best. A well-prepared surface will create a stronger bond between the decal and the model, resulting in a professional finish.

Cleaning the Surface

Cleaning the surface involves more than just a quick wipe-down. Start by using a soft brush or compressed air to remove loose dust and debris. Then, wash the model with a mild soap and water solution. Avoid harsh chemicals or abrasive cleaners that could damage the paint. Rinse the model thoroughly to remove any soap residue. After rinsing, allow the model to air dry completely or use a clean, lint-free cloth to gently pat it dry. For stubborn stains or residue, a specialized model cleaner or rubbing alcohol can be used, but test it in an inconspicuous area first to ensure it doesn’t damage the paint. A clean surface is the foundation for flawless decal application.

Tools and Materials You’ll Need

Gathering the right tools and materials will simplify the decal application process. You’ll need a sharp hobby knife or a pair of fine-tipped scissors to cut the decals. Tweezers are essential for handling and positioning the decals. A small bowl or container of water is needed for soaking the waterslide decals. Cotton swabs or a soft cloth are useful for removing excess water and air bubbles. Decal setting solutions and decal solvents can be helpful for achieving a professional finish. A ruler or measuring tape can also be useful for precise positioning. Ensure you have a well-lit workspace with plenty of space to work comfortably. Having everything prepared will save time and improve results.

Applying Diecast Decals Step-by-Step

Applying diecast decals is a meticulous process that requires patience and precision. Start by carefully cutting out the decal you want to apply, trimming as close to the edge as possible. Place the decal in lukewarm water for the recommended time (usually 15-30 seconds), allowing the adhesive to activate. Once the decal is loose from its backing, carefully remove it from the water. Position the decal on the model, using tweezers or a damp cotton swab to move it into place. Use a soft cloth or cotton swab to gently remove any excess water and air bubbles, working from the center outwards. This methodical approach will help you avoid common problems and achieve a professional result.

Cutting the Decals

Precision cutting is the first critical step. Use a sharp hobby knife or fine-tipped scissors to carefully cut out the decal. Trim as closely as possible to the printed image, avoiding any excess clear film around the edges. This will minimize any visible carrier film on the model. When cutting, work on a cutting mat to protect your work surface. Take your time and make slow, deliberate cuts, especially around intricate details. A steady hand and a sharp blade are crucial. Properly trimmed decals lay flatter and adhere better to the model’s surface.

Soaking and Positioning the Decals

After cutting, soak the decal in lukewarm water for the recommended time. This activates the adhesive on the back of the decal. Gently remove the decal from the water using tweezers or your fingers. Slide the decal off the backing paper and onto the model surface. Carefully position the decal using tweezers, a damp cotton swab, or a soft brush. Take your time, and use reference images or guides to ensure accurate placement. Be mindful of the decal’s fragility, and avoid stretching or tearing it during positioning. Accuracy at this stage ensures the final look matches your vision.

Removing Excess Water and Air Bubbles

Once the decal is in position, gently remove any excess water and air bubbles. Use a soft cloth, a cotton swab, or a specialized decal setting tool. Start at the center of the decal and work outwards, gently pushing the water and air bubbles towards the edges. This will ensure a smooth, bubble-free finish. Avoid pressing too hard, as this could damage the decal. If stubborn air bubbles remain, try pricking them gently with a needle and then pressing them flat. The key is patience and a delicate touch to achieve a flawless result.

Sealing the Decals

Once the decals are dry and free of bubbles, sealing them is recommended to protect them and create a uniform finish. Use a clear coat specifically designed for models. Apply the clear coat in thin, even layers, allowing each layer to dry before applying the next. This will protect the decals from damage, fading, and chipping. Consider using a matte or satin clear coat for a more realistic look. Be sure to follow the manufacturer’s instructions for the clear coat you choose. Properly sealed decals will look better and last longer, preserving the beauty of your model.

Troubleshooting Common Diecast Decal Problems

Even with careful preparation and application, problems can sometimes arise. Recognizing and addressing these issues is key to achieving a professional result. Decals may not adhere properly, they may crack or peel, or they may suffer from silvering. Each of these problems has specific causes and solutions. Understanding how to fix these issues will improve your skills and ensure that your final results look their best.

Decals Not Sticking Properly

If decals aren’t sticking, the surface may not be clean or the adhesive may not be activated. Make sure the model surface is free of any dirt, grease, or residue. Ensure that the water used to activate the decal is at the correct temperature, as too cold water can inhibit the adhesive. If the decal still won’t stick, you can try using a decal setting solution, which helps the decal conform to the surface and improves adhesion. Apply a small amount of setting solution to the decal and gently press it down. Allow it to dry completely. If problems persist, the decals may be old or of poor quality, and you might need to get new ones.

Decals Cracking or Peeling

Cracking or peeling can occur if the decals are too old, applied to a surface that is not perfectly smooth, or if the clear coat is applied too thickly. To prevent this, always use fresh decals and ensure that the model surface is smooth. Use a decal setting solution to help the decal conform to the surface. Apply the clear coat in thin, even layers, allowing each layer to dry completely before applying the next. If cracking or peeling has already occurred, carefully try to re-adhere the decal with setting solution or gently trim away the damaged area. In severe cases, the decal may need to be replaced.

Decal Silvering

Silvering occurs when air bubbles get trapped under the decal, creating a silvery appearance. This is often caused by applying the decal over an uneven surface or by not removing all of the water and air bubbles. To avoid silvering, make sure the model surface is perfectly smooth and clean. When applying the decal, carefully remove all excess water and air bubbles, working from the center outwards. If silvering occurs, try applying a decal setting solution to soften the decal and help it conform to the surface. You can also try piercing any trapped air bubbles with a needle and pressing them flat.

Advanced Diecast Decal Techniques

For the experienced modeler, advanced techniques can help achieve even more realistic and professional results. These techniques include using decal softeners and setters, as well as incorporating weathering techniques to add realism.

Using Decal Softener and Setter

Decal softeners and setters are specialized solutions designed to help decals conform to uneven surfaces and blend seamlessly with the model’s paint. Decal softener softens the decal, making it more flexible and easier to work with around curves and details. Decal setter helps the decal adhere to the surface and eliminates silvering. Apply the softener and setter after the decal is in place, following the manufacturer’s instructions. These solutions can dramatically improve the appearance of your decals, particularly on models with complex shapes or lots of detail.

Weathering Techniques for Decals

Weathering techniques can add realism to your diecast models by simulating the effects of wear and tear, fading, and dirt. Apply weathering effects, such as washes, dry brushing, or pigment powders, over the decals to integrate them with the rest of the model. This will make the decals look less like stickers and more like integral parts of the vehicle. Experiment with different weathering techniques to achieve the desired level of realism. Weathering is a great way to add detail and make your models look more authentic. Remember to seal the weathering effects with a clear coat.

Protecting Your Diecast Decals

Once your decals are applied, it’s important to protect them from damage and ensure their longevity. Proper storage and careful cleaning are key to preserving the appearance of your models.

Storing Your Models

Store your diecast models in a cool, dry place, away from direct sunlight and extreme temperatures. Direct sunlight can fade the decals and damage the paint. Avoid storing your models in areas with high humidity, as this can lead to mold or corrosion. Consider using display cases or protective boxes to shield your models from dust and accidental damage. Handle your models with clean hands and avoid touching the decals unnecessarily. Following these simple storage tips will help preserve your models for years to come.

Cleaning and Maintenance

Regular cleaning and maintenance will help keep your models looking their best. Dust your models regularly with a soft brush or a microfiber cloth. Avoid using harsh chemicals or abrasive cleaners, which can damage the decals and paint. If your models need more thorough cleaning, use a mild soap and water solution, and dry them carefully. When handling your models, be gentle and avoid applying excessive pressure to the decals. Periodic inspections will help you identify any potential issues early on. Taking good care of your models ensures that they remain a source of pride for years to come.